How SNS Works

Summary

Pulses (60 per second) of negatively-charged hydrogen ions are produced at the facility’s front end, they are accelerated to 88% the speed of light, converted to protons, and then they strike a heavy-metal target containing swirling liquid mercury (60 pulses per second) to generate neutrons through a process called spallation. The neutrons produced through this process are slowed down in a moderator and guided through beamlines to areas containing highly specialized instruments. There, neutrons of different energies are used in a wide variety of experiments on materials.

Ion Source

The SNS front-end system includes an ion source, beam formation and control hardware, and low-energy beam transport and acceleration systems. The ion source produces negative hydrogen (H-) ions—hydrogen with an additional electron attached—that are formed into a pulsed beam and accelerated to an energy of 2.5 million electron volts (MeV). This beam is delivered to a large linear accelerator (linac).

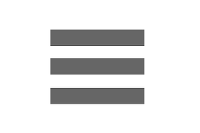

Linear Accelerator

The linear accelerator, or linac, accelerates the H- beam from 2.5 to 1000 MeV, or 1 GeV. The linac consists of normal conducting and superconducting radio-frequency cavities that accelerate the beam and a magnetic lattice that provides focusing and steering. Three different types of accelerators are used. The first two, the drift-tube linac and the coupled-cavity linac, are made of copper, operate at room temperature, and accelerate the beam to about 200 MeV. The remainder of the acceleration is accomplished by superconducting niobium cavities. These cavities are cooled with liquid helium to an operating temperature of 2 K (approximately -456°F). Diagnostic elements provide information about the beam current, shape, and timing, as well as other information necessary to ensure the beam is suitable for injection into the accumulator ring and to allow the high-power beam to be controlled safely.

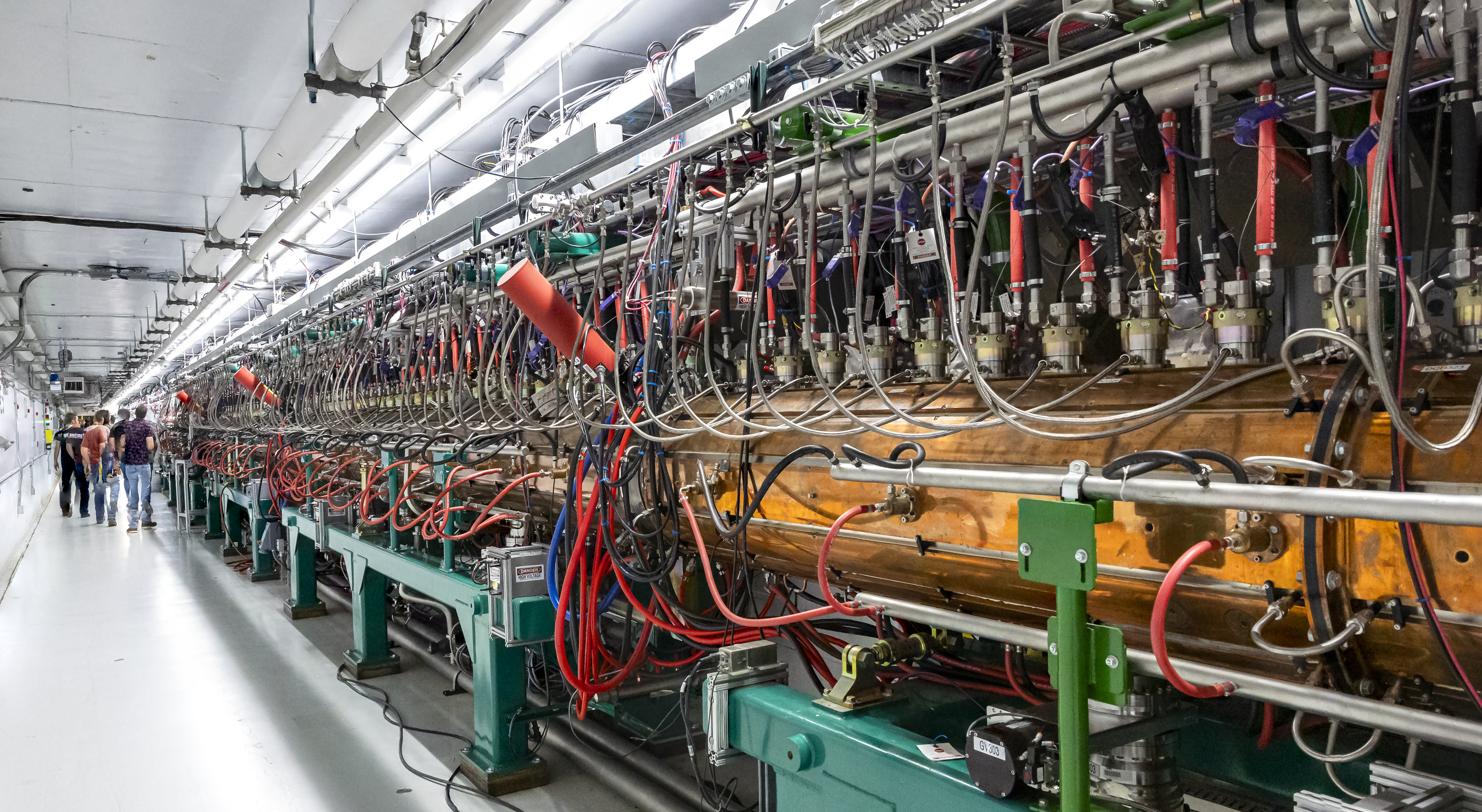

Proton Accumulator Ring

The accumulator ring structure bunches and intensifies the ion beam for delivery onto the mercury target to produce the pulsed neutron beams. The intense H- beam from the linac must be sharpened more than 1,000 times to produce the extremely short, sharp bunch of neutrons needed for optimal neutron-scattering research. To accomplish this, the H- pulse from the linac is wrapped into the ring through a diamond stripper foil that strips the electrons from the negatively charged hydrogen ions to produce the protons (H+) that circulate in the ring. Approximately 1,200 turns are accumulated, and then all these protons are “kicked” out at once, producing a pulse less than 1 millionth of a second (10-6seconds) in duration that is delivered to the target. In this way, short, intense proton pulses are produced, stored, and extracted at a rate of 60 times a second to bombard the target.

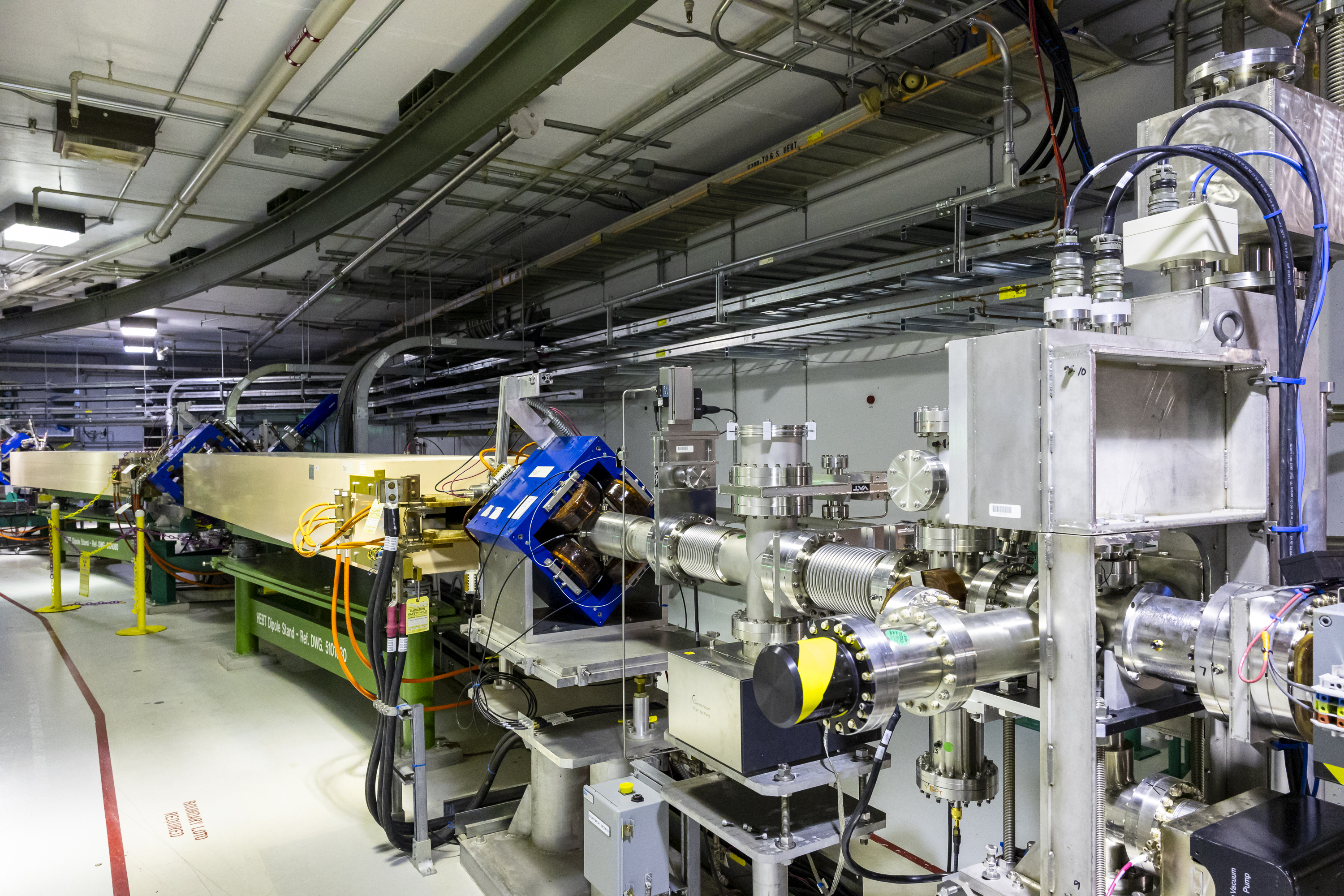

Target

The target vessel is a steel structure containing 20 tons of swirling liquid mercury. During neutron production 60 pulses of protons collide with the target vessel releasing energy roughly equivalent to a stick of dynamite exploding every second. When high-energy protons hit the nucleus of a mercury atom, 20 to 30 neutrons are "spalled" or released. Those neutrons are guided into beam tubes attached to instrument stations. The neutrons coming out of the target must be turned into low-energy neutrons suitable for research—that is, they must be moderated to room temperature or colder. The neutrons emerging from the target are slowed down either by passing them through cells filled with water (to produce room-temperature neutrons) or through containers of liquid hydrogen at a temperature of 20 K (to produce cold neutrons). The moderators are located above and below the target.

SNS instrument layout

Each instrument at SNS is unique and designed for certain types of experiments that require specific types of samples. Samples exposed to the neutron beam range from centimeters in width to meters. A variety of sample environments are available with each instrument, meaning that researchers can select from different environmental conditions, such as high temperature or high pressure, under which their experiment can be conducted.