One of the world’s oldest manufacturing processes has much in common with one of the newest: both can produce ceramic products, layer by layer.

For thousands of years, artisans have stacked and shaped “coils” of wet clay, layer upon layer, then heated the soft clay forms in kilns to produce extremely durable and decorative pottery. The artists—innovators and technicians in many ways—experimented with various temperatures, oxygen levels, and clay densities to produce different types of ceramics.

Similarly, scientists today are studying how to better manufacture and functionalize a wide range of advanced ceramic products, from superconductors and fiber-optic components to precision sensors and porous microscopic spheres for drug delivery. These and countless other applications have benefitted from the superior thermal and mechanical properties of ceramics.

At the Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL), researchers from the University of Nebraska-Lincoln (UNL) are using neutron diffraction to study ceramics produced layer by layer through laser additive manufacturing (LAM) processes. The highly penetrating and nondestructive nature of neutrons enables the scientists to observe the effects of the rapid heating and cooling that occur during laser-based manufacturing of complex ceramic objects.

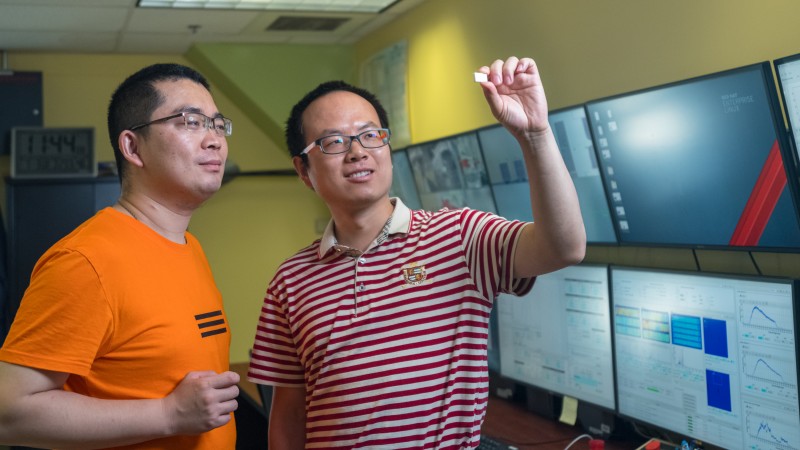

“Certain additive manufacturing processes use high-energy lasers to heat and compact powders into ceramics,” said Xiang Zhang, a graduate researcher at UNL. “To optimize the production of the ceramics for high-tech applications, we need to better understand how laser heating affects the materials at the atomic and molecular levels.”

The researchers used lasers at the UNL Laser-Assisted Nano Engineering Lab, headed by Yongfeng Lu, and the Nebraska Engineering Additive Technology Labs to melt and print samples of advanced ceramics. They then needed to determine how the intense heat and rapid phase changes from laser melting and rapid resolidification induced residual stress, chemical deviations, and defects such as pores and cracks in the ceramics, which can physically weaken the materials.

Neutrons are nondestructive, can penetrate deeply into bulk samples, and are highly sensitive to light elements such as oxygen and carbon in ceramics. The team therefore chose to use neutrons at the VULCAN engineering materials diffractometer beamline at ORNL’s Spallation Neutron Source (SNS), which efficiently characterized the multiple phases and microstructures in the samples.

“In recent years, additive manufacturing of ceramic components has proven to be relatively economical and energy efficient,” said Prof. Bai Cui, the primary investigator on the project. “We are using neutrons to determine how to optimize laser power and scan speeds as part of a proprietary laser-based method of fabricating complex ceramic structures that are difficult or impossible to produce by other methods.”

Specifically, the researchers were looking at how grain orientations, residual stress, and thermal stability in the ceramics are related to common LAM processes, including laser scanning and layering direction. Neutron diffraction enabled them to measure the grain orientations at different locations inside the ceramic samples and correlate texture development and other properties with production conditions.

Once the team has optimized laser power and speed, they plan to apply for a patent on the process.

The project was supported by the Office of Science and UNL.

SNS is a DOE Office of Science User Facility. ORNL is managed by UT-Battelle LLC for the DOE Office of Science, the single largest supporter of basic research in the physical sciences in the United States. The Office of Science is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.—by Paul Boisvert