The demand for lighter, stronger, and more durable materials for use in vehicles has never been higher. Companies are looking at new and advanced materials such as lightweight advanced high-strength steels (AHSS) to develop automotive components that help increase gas efficiency, reduce maintenance costs, and save lives.

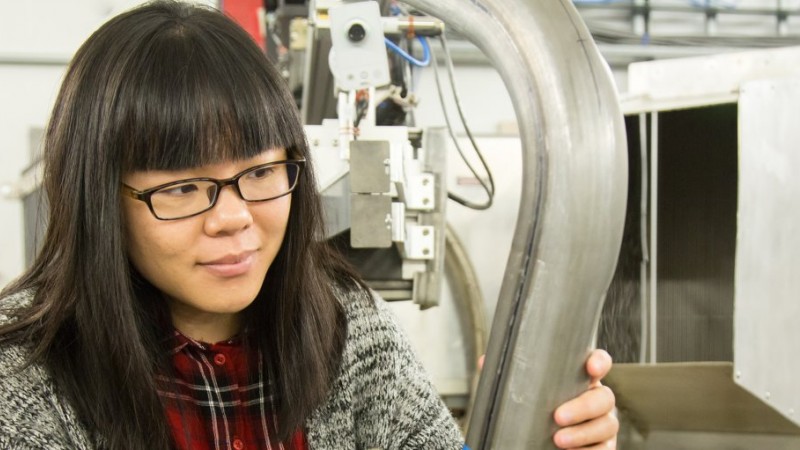

Researchers from the United States Steel Corporation (USS) recently used neutrons at Oak Ridge National Laboratory’s Spallation Neutron Source to better understand the properties of hydroformed AHSS and how it responds to residual stress introduced during manufacturing.

“Because this is a new material containing retained austenite, we need to have a better understanding of its performance,” said Lu Huang, USS industrial research engineer. “A better understanding of how this material responds to different manufacturing processes like stamping or hydroforming will help us validate engineering models that will in turn make it easier to design and produce auto components that are lighter, stronger, and more durable.”

Huang said the VULCAN instrument at SNS was the best tool for this research because of its ability to spatially resolve the residual stress in components. VULCAN’s sample environment can also accommodate large automotive components under observation in realistic operating conditions.

“Based on the literature, we knew others had used the neutron diffraction line-scanning technique to study the residual stress in weldments for welding,” Huang said. “We found that it is also very applicable when we look at as-formed parts, especially the ones formed with AHSS.”

Neutron diffraction provides nondestructive measurements of residual stress within the part formed with AHSS, making it possible to observe the intrinsic properties of the hydroformed parts and examine their emergence across various cross sections and lattices in great detail. This fundamental knowledge of the steel’s characteristics, Huang said, also laid the groundwork to probe the impact of residual stress in hydroformed steel parts on vehicle durability.

The researchers combed neutron data on residual stress distribution with computer simulations to see if they could improve the models that engineers use for designing and manufacturing auto parts.

“A vehicle is constantly undergoing fatigue, or cyclic force, so auto companies want to make sure that the vehicle will be safe within a certain lifetime,” Huang said. “Residual stress in the as-formed part may affect its fatigue performance. However, the effect of the residual stress on the fatigue performance is not usually incorporated in the simulation due to the lack of residual stress data or validated material models.”

The research team recently published their results in an SAE International technical paper that they hope will make it faster and easier for companies to design auto components that are lighter, more durable, and safer.

“We think our simulations and tests will help scientists and engineers to understand the fatigue performance of auto parts and how different manufacturing processes may affect it,” Huang said. “The residual stress data from our experiment may also set a new precedent of accuracy and specialization for validations and selections of material models in residual stress prediction or modeling.

Lu Huang’s coauthors include Xiaoming Chen from USS and Dunji Yu, Yan Chen, and Ke An from ORNL. The USS researchers received beam time at through the Industrial Applications Program at the Shull Wollan Center—a Joint Institute for Neutron Sciences.

SNS is a DOE Office of Science User Facility. UT-Battelle manages ORNL for the DOE’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit http://science.energy.gov/. – by Kelley Smith and Heidi Hill