Neutron facilities at Oak Ridge National Laboratory are aiding scientists in research to boost the power and efficiency of thermoelectric materials. These performance increases could enable more cost-effective and practical uses for thermoelectrics, with wider industry adoption, to improve fuel economy in vehicles, make power plants more efficient, and advance body heat–powered technologies for watches and smartphones.

Thermoelectric materials, typically metal compounds, can convert heat to electricity and vice versa in the presence of a temperature gradient, making them ideal for applications in waste heat recovery.

Thermoelectrics could capitalize on enormous amounts of unused waste heat produced by industrial operations, fossil-fuel power generation, commercial buildings, vehicles, and even people by converting that “lost” heat into useable energy. But so far their application has been limited to add-on technologies due to their low efficiency compared with conventional forms of energy generation.

To reach benchmarks set for standalone thermo-powered devices, scientists are now looking deeper—down to the atoms—into promising materials and methods to raise efficiency scores.

Working with a magnesium-antimony–based material, an international research team led by University of Houston physicist Zhifeng Ren has demonstrated a substantial increase in the alloy’s power factor, or total energy output, with a technique called defect engineering. By substituting cobalt atoms at strategic sites, researchers altered the pathway for electrons in a way that significantly improved their mobility. Neutron analysis performed at ORNL played a key role in verifying the method’s success.

The results, published in Proceedings of the National Academy of Sciences, are commercially relevant with a figure of merit, or ZT value, of ~1.7 achieved in thermoelectric efficiency. Most significant is the material’s increase in power factor at room temperature with a record jump from 5 to 13 μW·cm−1·K−2 that more than doubled the material’s total energy output.

The resulting power factor is far from the record of 106 at room temperature reached by Ren and others previously, but the method of boosting it could be applied to superior materials—particularly those with a power factor already above 100—to make the most efficient thermoelectrics even better.

The approach works by tweaking the compound’s atomic structure to overcome an inherent resistance in the flow of electrons that has limited the potential of thermoelectrics. At the atomic level, thermoelectric effects occur when carriers, or electrons, move in response to temperature. As electrons move through materials, they interact with atoms and get scattered on a circuitous path rather than a direct route, which results in inefficient energy conversion.

To produce more heat or more power with thermoelectrics, research has generally favored two avenues—increasing the carrier number or increasing carrier mobility. Designing a material or changing an existing material to accommodate more electrons is one solution, though it is tough to modify a material while maintaining its thermoelectric properties. Another option, adopted by the research team, is to fine-tune the materials at the atomic level to smooth the pathway for electrons to pass through with less resistance, thereby raising the material’s power factor.

The goal is not to create more space in materials, but rather to finesse the natural vibrations of atoms that govern their interactions with electrons by introducing “defects” that are not naturally present. By strategically placing the right amount of cobalt in the tweaked alloy, researchers are able to scatter the electrons in the alloy more efficiently.

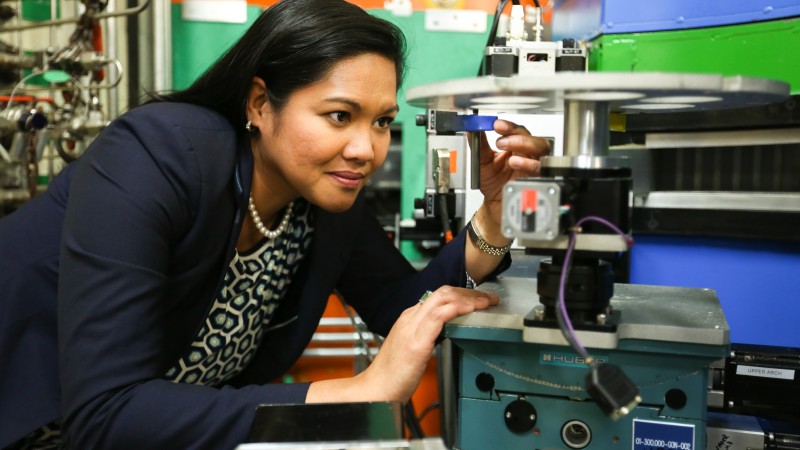

“This is a sophisticated way of improving thermoelectrics from the bottom up by controlling the way electrons scatter through materials,” said ORNL’s Clarina de la Cruz, who collaborated on the study.

As an instrument scientist for the HB-2A Neutron Powder Diffractometer at the High Flux Isotope Reactor, de la Cruz led the neutron scattering research to analyze the cobalt-doped Mg3Sb2 material.

A key objective for researchers was to pinpoint the precise locations of the replacement cobalt atoms introduced to verify their role as electron scattering centers. The work would not have been possible without the use of neutrons and their unique, nondestructive capabilities for observing matter at the atomic level.

Neutrons were essential because of the material’s complexity, explained de la Cruz. “To look at strategic substitutions on transition metals and identify very small concentrations of cobalt is no small task. Even without the added challenge of substitutions, some of these elements are so close together on the periodic table that deciphering them with x-rays or other methods is extremely difficult. You really need neutrons to solve this kind of problem.”

“Neutron science has become an integral part of the loop in boosting the performance of thermoelectrics,” said de la Cruz. “Researchers around the world who are designing new materials use ORNL’s neutron facilities to verify and improve upon their results, in this case, fueling future energy security.”

The research is supported in part by the Solid-State Solar Thermal Energy Conversion Center, an Energy Frontier Research Center funded by the DOE Office of Science.

The High Flux Isotope Reactor is a DOE Office of Science User Facility. UT-Battelle manages ORNL for the DOE Office of Science. The single largest supporter of basic research in the physical sciences in the United States, the Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.—by Ashley Huff

Article originally published in Neutron News.