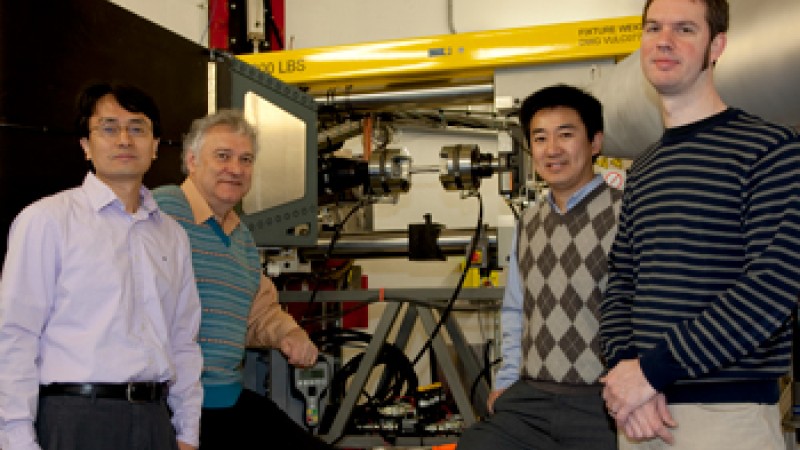

The engineering diffractometer VULCAN at SNS only recently completed commissioning, although it has been grazing across a significant range of user research in the past few months. The instrument was primarily conceived for large-scale deformation in industrial components and residual stress–related studies in welding. But the user applications have taken it across a varied field, from components for the ITER Project to the spatial mapping of the very small in chemistry and microstructure.

ITER, the International Thermonuclear Experimental Reactor, had been experiencing problems with a superconducting cable and brought it to VULCAN for study, says new lead instrument scientist Ke An.

The work done on the ITER cable shows how well positioned VULCAN is to tackle independent problems. The instrument has an open structure that can serve any sized sample. “You can put anything you want on there,” An says, “a lab sample, full-size sample, or a full, 3-meter test length of superconducting cable for ITER that is two inches in diameter.”

VULCAN also did the tests at speed. Many industrial projects have a critical turnaround time, and ITER was no exception. The VULCAN team managed to get samples of the defective cable on the instrument in less than two weeks. Results would typically follow in the third or fourth week, An says.

In another experiment, the first time such a study has been done in real time at a neutron facility by taking the advantage of neutron source power at SNS, the VULCAN team helped researchers to see the stages of lithium carbide during the real-time charge/discharge of a large format lithium battery for a PHEV (Plug-in Hybrid Electric Vehicle). They wanted to understand how the lithium ion is being absorbed into the carbide structure in batteries at work.

“We used high-intensity neutron diffraction to observe real-time charge/discharge of a battery,” An explains. “Not a slow discharge of hours but less than a one-hour, real-time discharge, in real conditions. The large format battery for PHEV is rated up to 40 Ah with a thickness of 8 mm, so it is difficult for conventional x-ray diffraction measurement.” To do this the researchers developed an advanced approach that enables neutron measurement at the fast charge/discharge rate. They were able to successfully resolve the discharge on a minute scale, with remarkable histograms emerging of the changes to the battery’s internal structure―the cathode and the anode―during charge/discharge.

The work showed the actual structural chemistry of what happens when lithium is transferred from one side of the electrode to the other. “Now we can use neutrons to see it. Once you understand this process, you can tune it. We used a pump-probe technique. Then we cycle the data. Then we sum them all together. We will push to do this at the microsecond level (millionths of a second) for fast transient phenomena in materials.”

VULCAN has a full user program this cycle, including industrial participants such as General Motors for batteries and fuel cell storage for cars.

The design philosophy called for a diffractometer with the highest desirable d-resolution, over a large angular range. How accurately you measure the value of d-spacing is its “resolution”; i.e., how close can 2 values of lattice plane be such that your experiment can still distinguish them.

For experiments that do not require such high resolution, the incident beam divergence can be relaxed to gain intensity at the sample position up to a factor of 3. Furnace, load frame, and other auxiliary equipment for in situ and time-resolved measurements are all integrated into the instrument.

An sees two features at VULCAN that make it the first of its kind in the world. One is the “one-of-a-kind” VULCAN multiaxial load frame. The other is the unique pulse data collection method that they have inserted directly into the beam line.

The $1.2 million VULCAN load frame was funded by the National Science Foundation through the University of Tennessee, Knoxville. Designed by the MTS Systems Corporation and the VULCAN team, it took five years to build.

The state-of-the-art load frame has four axes moving simultaneously as it applies tension and torsion to a sample. Normally such massive structures at neutron diffraction beam lines are uniaxial. The torsion capability allows researchers to do tests in multiple dimensions, as well as multiaxial cyclic fatigue up to 30 Hz—a rare condition. Load under heat by induction heater adds another capability to the unique load frame. A laser extensometer could measure length changes while the load and heat are being applied.

The loading features will be expanded over time. A microscope and infrared camera could look at specific points to enable multiprobe analysis of plane changes in a lattice, while observing local heating caused by local damage in the sample. Such features will give VULCAN powerful new capabilities.

A second unique VULCAN feature, and again the first of its kind in the world, is asynchronous neutron measurement of fast transient phenomena in materials. The method uses a special probing technique to take data from the sample under dynamic conditions, for example, under AC electrical field or cyclic mechanical load. The method has been integrated into the beam line to collect the neutron scattering data on a time scale of microseconds (millionths of a second).

“These are very fast processes. If they’re happening too fast, and repeating multiple times, then we can improve the statistics, ultimately to gather the data at microsecond intervals,” An says. “In previous cycles, we did it easily at millisecond (thousandths of a second) timescales with the existing neutron event-data collection. By developing a new meta (sample environment) event data along with the neutron event data, we measured transient phenomena in microseconds timescales. We can simply apply the special meta data structure into the beam line and turn it on. The data synchronization reduction can be performed by the high temporal resolution (100 ns) timestamp recorded in both the meta and neutron event data. Therefore, the sample environment and the neutron pulse do not need be synchronized at the time of measurement, like conventional pump-probe measurement, which reduces great amount of effort on system hardware and software integration. We have successfully used this method on our new load frame as well as AC electrical sample environment. Nobody has done this before at any pulsed neutron source.”

The novel data collection system and high neutron flux at SNS will open up new opportunities at VULCAN to study time-resolved phenomena occurring at high speed. The probe technique will be able to push resolution to the microsecond level. “The only limitation will be pulse width. This is something no one has done before,” An says.

SNS is funded by the U.S. Department of Energy (DOE) Office of Basic Energy Sciences.