Quantifying Dislocation Density in Cold Spray Al-Cu Coatings

October 5, 2020

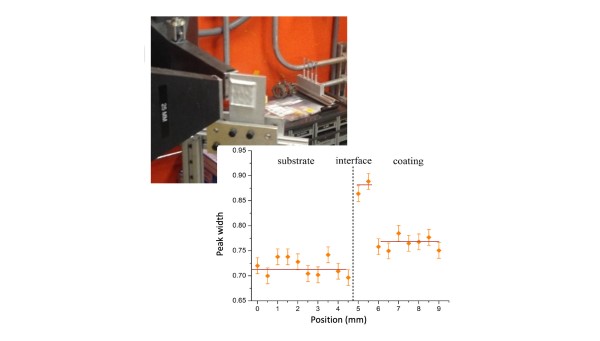

Top: Cold spray sample on neutron beamline.

Bottom: Larger neutron peak width indicates increased dislocation density in coating at interface.

Scientific Achievement

Increasing the Cu content of Al alloy cold spray coatings increases the dislocation density.

Significance and Impact

Cold spray is a new additive technique used to repair cracks in aluminum and aerospace alloys. Increasing the dislocation density enables optimization of the mechanical behavior of the repaired region, enhancing the component lifetime.

Research Details

- Al-Cu powders were prepared with varying Cu content and deposited by cold spray on aerospace alloy AA2024.

- The dislocation density in the near-surface region was determined from X-ray diffraction analysis.

- Neutron diffraction characterized the dislocation density in the bulk of the material and enabled mapping through the coating-substrate interface.

“Quantifying Dislocation Density in Al-Cu Coatings Produced by Cold Spray Deposition,”

Tian Liu, Mark D. Vaudin, Jeffrey R. Bunn, Tamas Ungár, and Luke N. Brewer,

Acta Materialia, 193, 115-124 (2020). DOI: https://doi.org/10.1016/j.actamat.2020.04.040