The generation of bioethanol from lignocellulosic biomass holds great promise for renewable and clean energy production. However, this type of biomass is a complex, composite biological material that shows significant recalcitrance to enzymatic breakdown into sugars that can be used for fermentation, currently making it cost-ineffective as an ethanol source. The present research provides insight into the consequences of dilute acid pretreatment of biomass through direct observation by small-angle neutron scattering (SANS) of structural features in cellulose extracted from switchgrass over length scales from 10 to 6000 Å.

Researchers in the Center for Structural Molecular Biology at ORNL and the Institute of Paper Science and Technology of Georgia Tech used SANS to probe the structural impact of dilute acid pretreatment of lignocellulose from switchgrass, a complex laminate material composed of lignin, hemicellulose, and cellulose. The presence of lignin on the cellulose fibrils and dense crystalline fibrous packing of cellulose impede its subsequent hydrolysis. Dilute acid pretreatment dissolves the hemicellulose and redistributes the lignin associated with the cellulose fibrils. The study investigates the interplay of the biomolecular components of lignocellulose during the pretreatment process.

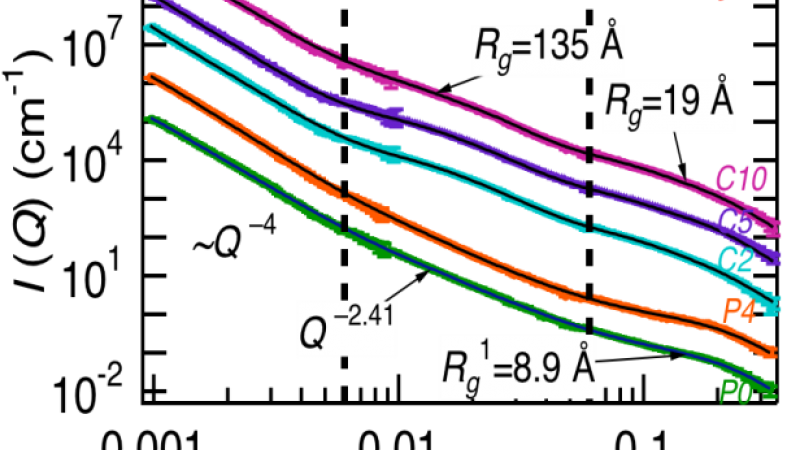

The researchers compared the scattering signatures of native switchgrass biomass and switchgrass that had been pretreated with hot dilute sulfuric acid. While the SANS data demonstrate that the switchgrass materials are very similar at length scales greater than 1000 Å, the materials are different at the shorter length scales studied. In particular, the characteristic dimensions determined from the high-Q SANS data, which arise from the cellulose fibrils themselves, show that the crystalline cellulose fibril diameter increases from about 21 Å before to 42 Å after treatment. SANS also shows that lignin concurrently undergoes a redistribution process and forms aggregates with 300-400 Å particle size.

The study suggests that hot dilute sulfuric acid pretreatment effectively decreases recalcitrance by making cellulose more accessible to enzymes through lignin redistribution and hemicellulose removal. On the other hand, the apparent increase in cellulose microfibril diameter may indicate a cellulose “re-annealing” that would be counterproductive and may limit the efficiency of the dilute sulfuric acid pretreatment process. The ability to extract meaningful structural information from different native and pretreated biomass samples will enable evaluation of various pretreatment protocols for cost-effective biofuels production.

Research conducted at the High Flux Isotope Reactor was funded by the U.S. Department of Energy Office of Basic Energy Sciences.

Published Work

S. V. Pingali, V. S. Urban, W. T. Heller, J. McGaughey, H. M. O’Neill, M. Foston, D. A. Myles, A. J. Ragauskas, and B. R. Evans, “Breakdown of Cell Wall Nanostructure in Dilute Acid Pretreated Biomass,” Biomacromolecules, Article ASAP, DOI: 10.1021/bm100455h.